- Din Iso 2768 Mk Tolerances

- Iso 2768 Mh Tolerances

- Iso 13920 Free Download

- Iso 13920 Bf

- Iso 2768 Mk Tolerances

- Iso 2768 Mk-e Meaning

Microsoft Word - ISO 2768 fH general tolerances Author: mra Created Date: 10/6/2010 6:06:26 PM. Our website uses cookies. Cookies are small text files held on your computer. They allow us to give you the best browsing experience possible and mean that we can understand how you use our site. ISO 2768 – m or general tolerance ISO 2768 – m For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1. General tolerances for form and position according to DIN ISO 2768-2. DIN ISO 2768 mk tolerances I do not have a full copy of the DIN but I do have some notes and a brief discription of how the tolerances are supposed to work but I still dont quite understand it. The parts are shafts and couplings and have to fit bearings so I know some of the tolerances are going to be plus and some are minus. Normativa En-22768 ISO-2768 Pag. 1 di 4 Via Bersella, 5 - 42018 SAN MARTINO IN RIO (RE) Italy - P.Iva 6 www.omp-italy.com - Tel.+39 0522 698931 Tolleranze generali per dimensioni lineari e angolari-Le tolleranze di tutti i disegni OMP, ove non sia espressamente riportata la tolleranza, sono.

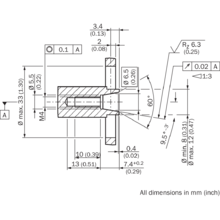

Value is expressed in mm

Value is expressed in mmAccording to DIN ISO 2768-2General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings. If smaller tolerances are needed or bigger ones are more economical, Tabular 1 Limits for linear measures

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. Tabular 2 Limit measures for radius of curvature and chamfer height

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben. Din Iso 2768 Mk TolerancesTabelle 3 Grenzabmasse für Winkelmasse

Iso 2768 Mh Tolerances

ISO 2768 – m or general tolerance ISO 2768 – m For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1. According to DIN ISO 2768-2  Iso 13920 Free DownloadDIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position. Iso 13920 BfIf smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101.  Iso 2768 Mk TolerancesGeneral tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing. Iso 2768 Mk-e Meaning

Ramo AB ansvarar ej för eventuella felaktigheter i ovanstående information. Ramo AB takes no responsibility in the eventuality of errors in the above information. Loadingclub484 © 2021

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||